The current domestic medical plastic products industry in technology and product innovation capacity is relatively weak, with independent intellectual property rights of the product is relatively small. With the development of China's economy, people's quality of life requirements and the continuous improvement of medical products, China's medical plastics industry market prospects are extremely broad. After joining the WTO, we are faced with opportunities and challenges, we have reason to believe that: in the near future China's medical plastics industry will have a rapid development.

20 years with the development of medical equipment, medical plastic products in the medical cause of play an increasingly important role. In 1997, the world's medical device output value reached 137 billion US dollars, while medical plastic products accounted for 15% of its share, China's medical output value, in 2000 reached 30 billion yuan, medical plastic products about 40 billion yuan, 1999 The annual registration of medical equipment enterprises 5700, and the production of medical plastic products business accounted for more than 600 enterprises, accounting for 10%.

Statistics from the digital point of view, China's medical plastic products in the past 10 years has been rapid development, and the number of high-tech areas. It is speculated that by 2005 the medical device market will grow by 40%, followed by medical plastic products can grow, its market potential is huge. China's medical plastic products and foreign advanced level gap is still large, mainly in:

1, due to the basic industrial backwardness, medical plastic products required for the incomplete classification of raw materials, quality standards are not standardized, the lack of development of medical plastic raw materials business enterprises, such as: as one of the best treatment of catheter treatment of medical polyurethane materials, market It is difficult to buy, only to foreign imports, so most of the domestic use of PVC pipe materials, the performance of its product quality and imports of similar products there is a certain gap, so that domestic products in the marketing and lack of ability to compete with imported products.

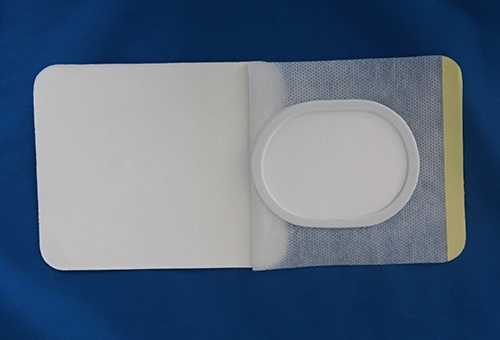

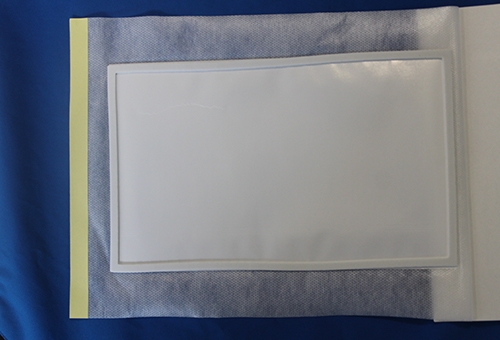

In addition, like dialyzers, oxygen devices are medical clinically mature products, they can not be used in the material PU film as a hollow fiber membrane potting material, the annual consumption of medical PU film material dozens of tons , All rely on imports, so the development of medical polyurethane materials is also an important topic in the plastics industry, to solve the medical PU film material localization, to promote the development of medical plastic products is of great significance.

2, medical plastic products manufacturing enterprises of the basic facilities, low level of management, product quality and poor stability, poor reliability. The national production of medical plastic products business nearly 600, many of which are behind the enterprise infrastructure, not completely according to one-time sterile medical equipment production and management practices to do, backward processing equipment, management staff quality level is low, or even workshop type Of the labor-intensive, the production environment can not meet the GMP standards, technical strength is weak, which are lagging behind the development of China's medical plastics business, therefore, domestic medical plastic products, often quality problems continue, although the National Pharmaceutical Board has increased supervision Efforts to increase the intensity of punishment and crackdown, but to make our medical plastics enterprises have a fast development, enterprises must be in accordance with laws and regulations to do, through the ISO9000 quality system certification, standardize the behavior of enterprises, improve quality awareness.

3, product technology structure behind the development of contemporary science and technology. Most of the materials and products of the technical performance of middle and low products, a considerable number of products did not form economies of scale production, full labor productivity is low, the lack of market competitiveness.

4, select the better basic conditions of the region, through the efforts of enterprises combined with government policy support, through the establishment of a number of powerful joint development research, production, marketing as one of the industrial center, in some of the national economy Product competition with foreign enterprises in order to cope with China's accession to the WTO after the competitive pressures facing enterprises. According to the track of the market economy concerned about the biomedical medical plastics industry, limited low value-added, low-tech products to increase the number of enterprises, the focus of the construction of several large-scale enterprises of large-scale basic conditions of good enterprises, eliminate backward small and medium enterprises, Establish the competition mechanism of the survival of the fittest.

5, in recent years, China's medical plastics industry is developing rapidly, the average annual rate of 15% to 20% increase, but the domestic medical plastic products is a new industry, the starting point is lower, compared with the international advanced countries is also larger, for example, , In 1982 China's medical plastic output value of only 78 million yuan, less than 100 million yuan. Even in 1997 the value of medical plastics increased to 3 billion, medical equipment 24 billion output value, medical plastic products accounted for 12.5% of its share in 1999, medical plastic production value of 3.8 billion, only the world's medical plastic production value of 1% to 2% , The domestic per capita consumption is only foreign developed countries 1% to 5%.